TPV waterstops for chemical, industrial, & environmental applications

October 17, 2022

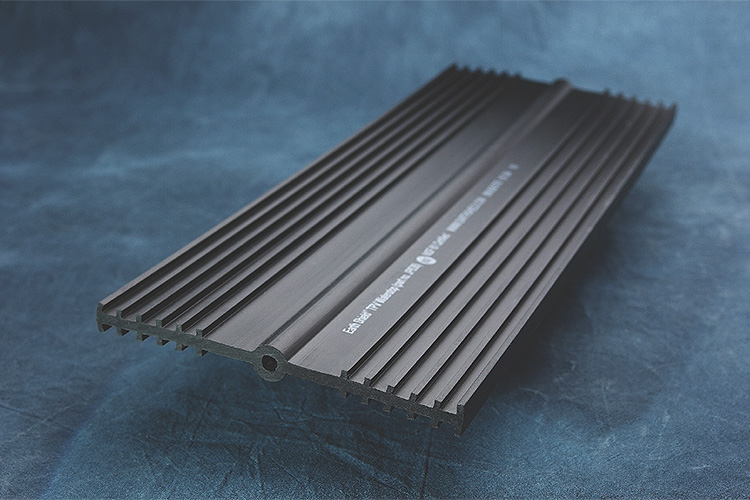

TPV WATERSTOP

Earth Shield® Thermoplastic Vulcanizate Waterstop (TPV) (aka TPE-R) is used as a fluid-tight diaphragm, embedded in concrete, across and along the joint, for primary and secondary containment structures. Earth Shield® Chemical Resistant Waterstops are resistant to a wide range of oils, solvents, and aggressive chemicals. Alcohol, ketones, glycols, esters, and aqueous solutions of acids, salts, and bases have little effect on Earth Shield® Thermoplastic Vulcanizate Waterstop.

- tpv waterstop sweets product catalog (PDF)

- tpv waterstop submittal package (PDF)

- tpv waterstop installation guides

- tpv waterstop specifications (PDF)

- tpv waterstop specifications (MS Word)

- tpv waterstop CAD details (PDF and DWG)

- tpv waterstop chemical resistant chart

- tpv waterstop sds sheets

- tpv waterstop technical data sheet (TDS)

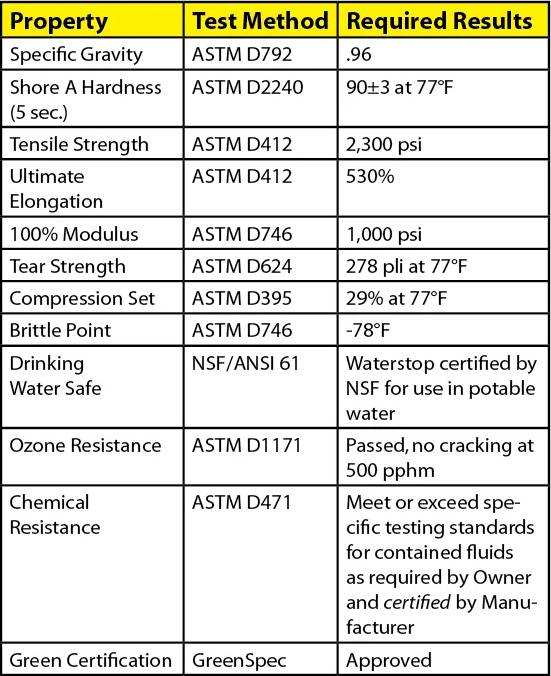

Unlike polyvinyl chloride (PVC) waterstop, Earth Shield® waterstop contains no plasticizer, stabilizer, or filler to leech out when exposed to chemicals, fuels, ozone, and aggressive industrial fluids. Also, unlike PVC waterstop, Earth Shield® can withstand prolonged exposure to high and low temperatures (-78°F to 275°F long term) without detrimental effect. Earth Shield® TPV Waterstop is NSF Standard 61 certified for use in drinking water and is made of a recyclable polymer, so it’s good for your health and the environment.

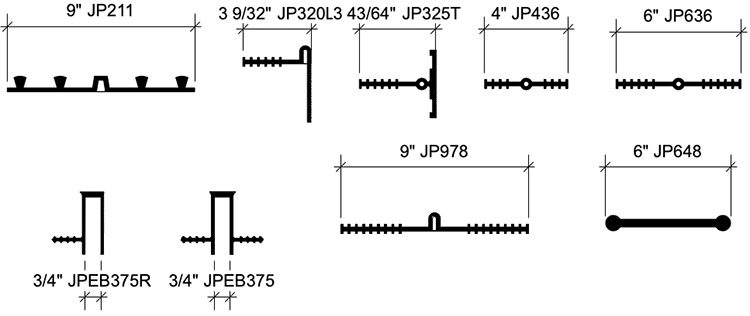

The superior chemical resistance of Earth Shield® Thermoplastic Vulcanizate Waterstop is enhanced by the use of a ribbed centerbulb configuration, which is available in a 4, 6, and 9-inch width. This provides for greater mechanical bonding with the concrete and a barrier against migration of liquid flow around the waterstop. The ribbed centerbulb style also allows for joint movement and may be used in above or below grade applications. Additional shapes are available for retrofit, extreme expansion, stainless steel and base seal applications.

POPULAR TPV WATERSTOP PROFILES

The chemical resistance of the waterstop material, exposure, temperature, chemical concentration of the contained material, and any requirements for joint movement should be considered when selecting the waterstop material.- ACI PRC-350.2R-21

Install Earth Shield® TPV Waterstop in all concrete joints. Waterstop should be centered in, and run the extent of the joint. All changes of directions should be prefabricated (see Shop Made Fittings), leaving only butt-welding for the field. If installing in an expansion joint, keep center bulb unembedded to allow it to accommodate movement as designed. Use optional factory installed brass eyelets (or #3 hog rings) and tie wire to secure waterstop to reinforcing steel to avoid displacement during the concrete pour. Splice straight lengths of waterstop and Shop Made Fittings to straight lengths, with an ST-10® In-Line Waterstop Splicer with the iron temperature set to 410°F to 430°F.

Qualified technical assistance is available during any phase of your construction project.

Standard 3-part Specifications are available at our website in Microsoft Word and Adobe PDF format, and upon request in printed and a variety of computer word processor formats. Call our Technical Sales Staff for additional help with your specification.

SUGGESTED PROPRIETARY SHORT FORM GUIDE SPECIFICATION

TPV CHEMICAL RESISTANT WATERSTOP

Waterstop indicated in drawings and specifications for contraction (control), expansion and construction joints shall be Earth Shield® Chemical Resistant Waterstop Part No. #### [Designer insert appropriate part number here] as manufactured by J P Specialties, Inc.; Murrieta, CA 92562; Phone 951-763-7077

- Thermoplastic Vulcanizate (TPV) Waterstop shall conform to EPA Title 40 Section 265.193. The suitability of the waterstop for a specific application should be determined by specific testing for that particular requirement per ASTM D471. Project-specific certification to be provided by the manufacturer.

- Thermoplastic Vulcanizate (TPV) Waterstop shall be independently certified for use in potable water per NSF/ANSI Standard 61. Third-party certified documentation to be provided by the manufacturer.

- No equals or substitutions allowed.

To earn NSF/ANSI 61 certification, J P Specialties’ Earth Shield® TPV Waterstop was subject to rigorous testing and evaluation to verify the product met requirements for use in treating drinking water. NSF International also audited J P Specialties’ manufacturing facility to verify compliance with the standard requirements.

@waterstopking #waterstopking #waterstop #dewalt #concrete

Company:  JP Specialties, Inc.

JP Specialties, Inc.

Product: TPV Waterstop

Source: https://www.jpspecialties.com/waterstop-products/tpv-waterstop/

Tags:

Construction

Waterproofing

Bio-San C500 - A Unique Way Of Protecting Concrete In Sewage Conditions (September 21, 2022), Why Spray Foam? Outlast and outperform fiberglass: cutting energy costs (September 9, 2022), Sustainable Farm & Spa Oasis South Of Nashville Uses Penetron For Enhanced Durability (September 7, 2022), Epoxy Floors for Fire Rescue/EMS Facilities (September 2, 2022), Expert studies show that the Xypex non-soluble crystalline structures protect & heal concrete from within (April 12, 2022), Defending Concrete Durability – the Importance of an Impermeable Concrete Cover (February 18, 2022), Ozone Resistant TPV Waterstops (January 24, 2022)