How 3D Printing is Helping the Coronavirus Cause

July 2, 2021

As our country continues the fight against the coronavirus, businesses, health care providers, and even homebound DIYers are turning to a familiar printing method that manufacturers have used for decades.

3D printing, also known as additive manufacturing, is making headlines as a means to help hospitals and health care workers who are experiencing a shortage of medical equipment and Personal Protective Equipment (PPE) during the coronavirus pandemic.

With more than a million confirmed cases in the United States, demand for this equipment is at an all-time high and has put a strain on the supply chain. 3D printing has limitations and may not be a long-term solution, but we’ll explain how it has served as an interim stop-gap with initiatives around the world.

3D printing refresher course

The 3D printing process uses a computer-aided design (CAD) to create a solid, three-dimensional object. A 3D printer shapes and molds materials through layering, mainly steel or plastic, to achieve the design, size and structure set forth by a digitally formatted design.

Over the years, 3D printers have decreased in cost and increased in speed and effectiveness. The process of 3D printing generally takes four to 18 hours to complete. This is why you’re seeing 3D printing take off and why it's one of the top architectural trends for 2020. A recent report from Wholers predicted that number to reach $15.8 billion in 2020.

Out of necessity due to the coronavirus, 3D printing has exploded because you can brainstorm an idea, come up with a design and create a prototype within hours.

3D nasal swabs

Two problems became clear once the U.S. felt the coronavirus impact: the need for testing and the need for a treatment option. As widespread testing ramped up around the country, demand for nasal swabs swelled.

For background, the same cotton swabs you’ll find in your bathroom aren’t meant for diagnosing COVID-19. The test uses long nasopharyngeal swabs — this explains why many patients complain about the discomfort associated with the tests — to collect samples from your nasal cavity and upper respiratory tract.

In the months since shortages became evident, a consortium of business and medical institutions joined forces to bolster swab production. Together, they’re capable of manufacturing 4 million 3D printed swabs per week.

Elsewhere, Origin created a swab design that completed a Phase III clinical trial and received validation from Harvard’s Beth Israel Deaconess Medical Center. The 3D printing company hopes to produce 190,000 swabs per day.

In April, a joint effort from the University of South Florida Health and New York-based health care provider Northwell Health helped design nasal swabs for mass production. They enlisted Boston-based Formlabs to help with manufacturing, using 3D printing and resins to form the swab. The company can produce as many as 300 swabs during a single print and hopes to increase production to 100,000 swabs per day.

HP Inc., which many know for its computers and laptops, helped manufacture nasal swabs via 3D printing. It took two days for the HP team to design, print, and ship the nylon swabs for clinical testing. The swab, built with a handle, flexible neck, and a tip, measures 15 centimeters. Once it received validation, HP moved on to the next step of working how to mass produce it.

Bridging the PPE gap

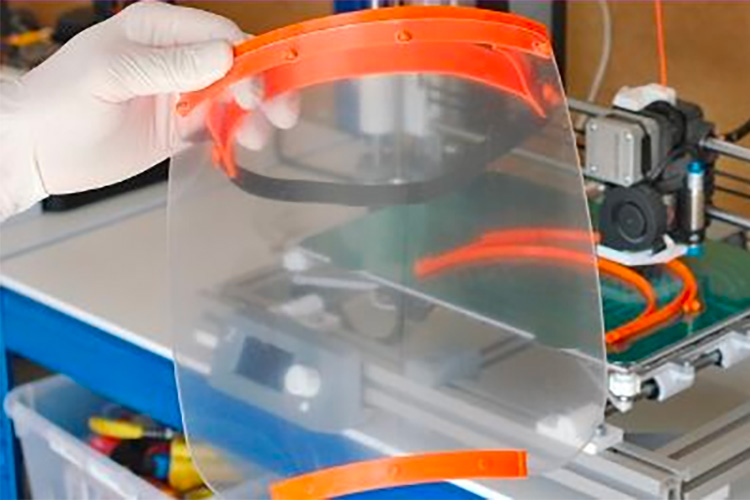

By March, hospitalizations spiked across the country, and the need for PPE increased by the day. Doctors and nurses were running out of masks, face shields, and other medical supplies to protect themselves and patients against the coronavirus. Meanwhile, ventilators, a needed piece of equipment to help severely ill patients breath, became scarce.

The U.S. Food and Drug Administration cautioned 3D-printed PPE can provide a physical barrier, but it doesn’t protect you from fluids and other airborne particles like some masks and N95 respirators do. Still, large companies and small local businesses around the country used their own expertise in 3D printing to provide much-needed resources to those in need.

Some companies have designed 3D printing ventilator connectors, a Y-shaped device that allows multiple tubes to run from one ventilator, thus doubling the access to other patients. Through 3D printing technology, Prisma Health developed VESper, a ventilator expansion device that doesn’t impact patients connected to the same machine. It also filters bacteria and viruses in the tubing. The FDA provided Prisma with an Emergency Use Authorization, and Ethicon Inc. is distributing the device to health care providers at no cost.

Many companies unaffiliated with 3D printing for health care supplies have switched gears to help meet demand. For example, popular car manufacturer Volkswagen announced it was using 125 industrial 3D printers to produce ventilators and medical devices. Ferrari, an automaker known for its luxury vehicles, used its 3D printing capabilities to make valves that turn snorkel masks into respirators.

SmileDirectClub, a teledentistry company based in Nashville, Tennessee, began using its 3D print manufacturing capabilities to make face shields and other PPE for health care and government organizations. SmileDirectClub can produce 7,500 face shields per day.

In Florida, a 3D printing company that typically specializes in building drones helped start the American Mask Rally to provide reusable face masks to health care workers.

HP has produced more than 150,000 parts for medical applications. The company has designed face shields, masks, mask adjusters, wrist covers, ventilator components and hands-free door openers (more on that later).

With so many companies eager to help, several federal organizations, including the National Institutes of Health, the U.S. Food and Drug Administration, and the U.S. Department of Veterans Affairs, teamed up to form a 3D print exchange where you’ll find hundreds of designs reviewed for clinical use. The options include face shields, face masks, and surgical mask bands to improve comfort during long shifts.

Creating a safer environment

One of the most concerning aspects of the coronavirus is how easily it can spread from person to person through air droplets or when touching contaminated surfaces. Researchers learned the coronavirus can live on certain surfaces anywhere from a few hours to a few days. This is why hand washing and proper cleaning techniques are essential.

Surfaces, such as door handles, elevator buttons, and railings, can become contaminated in high-traffic areas where thousands of people touch them each day. As a result, companies incorporated 3D printing to make plastic door openers you can operate with your arms.

European 3D printing company Materialise created a hands-free door opener, where you place your arm in a plastic clasp to prevent your hands and fingers from touching door knobs. The company then provided the design for free and encouraged others to produce the door opener.

The simple design is easy to install over your existing door handle with four screws and four nuts. After downloading the design, the company encourages you to customize it to your liking for business or personal use. You can adjust the shape, width, screw type, and handle sizes.

BCN3D, a 3D printing company in Spain, tweaked Materialise’s design and created a hands-free door opener that uses just three cable ties to secure it to an existing handle.

Materialise also used 3D printing to create a hands-free shopping cart handle. Instead of using your hands to push a cart, a simple screw-on plastic device allows you to handle and steer the cart with your arms. Grocery store employees would still have to wipe down carts, but these handles would limit the spread of the coronavirus by avoiding a contaminated surface that you could touch and transfer to your face. Or, as signs on European shopping carts read, “do less harm, use your arm.”

As we start to return to our normal lives, contact us if you’re inspired to start a custom metal grille project. You can browse our product catalog or request a quote for more information.

@CocoMetalcraft #CocoMetalcraft #architecture #metalcraft #design

Company:  Coco Architectural Grilles & Metalcraft

Coco Architectural Grilles & Metalcraft

Source: https://www.cocometalcraft.com/how-3d-printing-is-helping-the-coronavirus-cause

Tags:

3D

Wall Coverings: a variety of options (July 24, 2020), Choosing 3D Bamboo EcoTile Wall Panels (December 20, 2019), 5 Cutting-edge ideas to use 3D textured designs in your home today (January 2, 2018)

Coronavirus

Social distance seating: portable cubicle seating systems for multipurpose venues (June 9, 2021), Help reduce the spread of COVID-19 and protect your employees with VirusGuard™ products (April 21, 2020)

COVID-19

Social distance seating: portable cubicle seating systems for multipurpose venues (June 9, 2021), Armstrong VidaShield UV24 Air Purification System (January 15, 2021), Protective Partition Dividers (January 13, 2021), Top five tips for creating a rooftop deck (December 18, 2020), Armstrong Ceiling & Wall Solutions 24/7 Defend Portfolio (December 14, 2020), Armstrong Ceiling & Wall Solutions Introduces CleanAssure™ Portfolio of Disinfectable Products (November 16, 2020), Boon Edam Publishes Whitepaper on Effect of Pandemics on Entrance Security (November 6, 2020), Building Owners Seeking Healthier, Safer Indoor Spaces Can Turn to New Armstrong Ceiling Solutions to Ease COVID-19 Pandemic Concerns (October 16, 2020), It's Now Black Friday Every Day: How to Manage the Influx of Packages (September 2, 2020), 5 Questions With Jim Edgeworth, Residential Sales Director for The BILCO Company (August 31, 2020)

Grilles

New Download - The Architect’s Guide to Sun Control Products Brochure (May 26, 2021), The EconoSpan® louver and screen system is ideal for roof top equipment screening or other applications with large areas requiring concealment and ventilation (April 30, 2021), Metalwork in the 1950s (July 17, 2020), How Laser Cutting Works (July 25, 2019), Custom Laser-Cut Decorative Metal Panels (January 28, 2019), 3 Functions of an Entrance System (August 31, 2018), Louver and Architectural Solutions (August 23, 2018), How to Choose the Right Perforated Grille for Your Project (August 9, 2018), Data center protection (April 15, 2018), Linear Grille Wall Cladding (March 14, 2018)

Ventilation

The Daylighting Difference: Restaurants (June 23, 2021), The EconoSpan® louver and screen system is ideal for roof top equipment screening or other applications with large areas requiring concealment and ventilation (April 30, 2021), What are the Steps for Creating a Dynamic Wall? (April 14, 2021), STC or OITC? How to select the proper sound rating for automatic smoke vents (February 3, 2021), New Advanced Thermal Dispersion Airflow Measurement System Flyer (November 20, 2019), Benefits of specifying complete masonry veneer wall systems (January 23, 2019)