architecture - engineering - construction

Case Study: Designing and Manufacturing Steel Stackable Test Weights

Other News

Other News Subscribe to FREE newsletter

Subscribe to FREE newsletter

| Apr 12, 2021 |

For people working with or around crane/hoist equipment, test weights are essential in ensuring and certifying a safe work environment. MarsMetal Company, a North American leader in designing and producing test weights, recently worked with an industrial commercial client based in the Midwest USA to meet their custom requirements for test weights.

Challenge: Rugged, Transportable, and Stackable

The client approached Mars Metal with the requirement of producing test weights which could be handled by a crane hook or forklift. These test weights had to be rugged, easily transportable, and with a limited footprint of 48 square inches or less. The client required a variety of different weights and hoped they would be stackable and interchangeable.Solution: Steel Stacking Test Weights

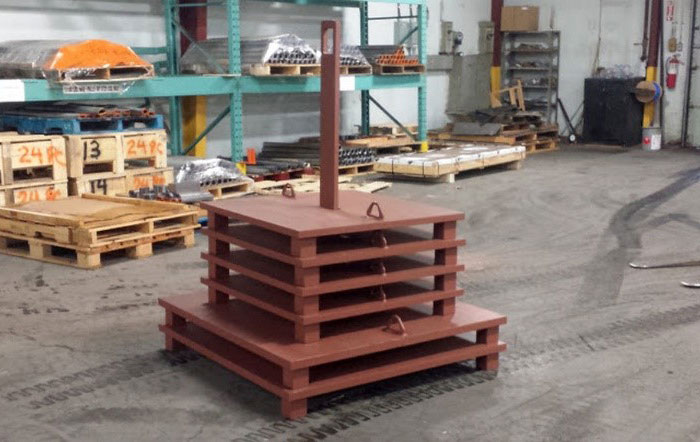

Working with our team of designers, Mars Metal was able to solve the client’s problem by providing all steel stackable weights.We designed a square-shaped base post-weight which had a centered steel post with a built-in lifting eye at the top. The next step including designing several individual weights consisting of more large square plates with a hole in the center to drop over the base weight. Legs and lifting eye pads were added to each weight, which allowed an operator to pick them up with a crane hook or forklift. The inclusion of the post allowed the test weights to be easily interchangeable, making the process of only using the required weight seamless. Mars Metal designed these test weights according to the custom 48 square inches specifications of the client with 125% load safety factor.

The client’s other options were test weights made of concrete blocks or water weights which would not have even met half of their custom requirements. In comparison, MarsMetal provided a design which met all their needs within reasonable delivery time.

“It was a dream to work with Mars Metal who not only delivered exactly what was needed at an affordable price but also shipped in a very quick time frame. They exceeded all our expectations. I would highly recommend them for test weights.”

MarsMetal designs and produces standard and custom lead test weights that help ensure the safety of elevators, aircraft and cranes/hoists. Our products exceed industry standards for all your testing applications.

@MarsMetalCo #MarsMetal #leadcasting #leadfabrication #leadfinishing

For other relevant searches, you might want to try: