Which Products Work Best for Exterior Soffits and Ceilings?

Other News

Other News Subscribe to FREE newsletter

Subscribe to FREE newsletter

| Mar 28, 2022 |

New Insights for Specifying Exterior Soffits and Ceilings

Exterior ceiling and soffit areas are common to many building types and require products that are specially formulated to resist sag caused by exposure to excessive heat and humidity. In commercial construction, examples include covered walkways, open parking garages, bank teller drive-through canopies, marquees, or the underside of any upper floor or roof that extends past the exterior wall below. Residential applications include breezeways, covered porches and the soffits formed by the eaves of a house.

Historically, gypsum soffit board was used for exterior soffits. This product was distinguished from interior gypsum board by its moisture-repellent paper and special additives for sag resistance. Traditional moisture-resistant gypsum board, or “green board,” utilized wax in the gypsum core to achieve its moisture resistance and was unsuitable for exterior soffits due to its poor sag resistance.

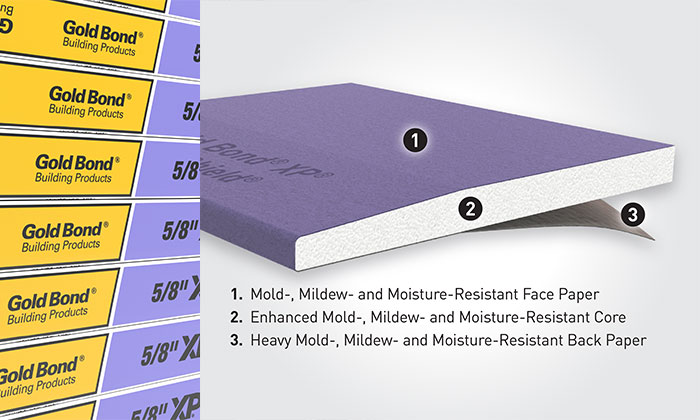

Mold- and moisture-resistant gypsum boards today rely on a different technology for moisture resistance. The paper and gypsum core are treated with silicone, which eliminates the sag problem caused by wax content in older products. As a result, gypsum board products typically specified for wet or semi-wet interior areas, such as Gold Bond® XP® Fire-Shield® Gypsum Board, are also suitable for use in exterior soffits, eliminating the need for a separate soffit board product.

Multiple factors should be reviewed when selecting the appropriate gypsum substrate for exterior soffits and ceilings. We recommend that you talk with your Construction Design Manager prior to specifying.

“There are several Gold Bond gypsum board products for soffit applications. The advantage of having a choice is the possibility of using the same product in the soffit that is already being installed elsewhere on the job. Did you specify mold- and moisture-resistant gypsum board, like Gold Bond XP Gypsum Board, for the interior of the building? Do you have an exterior soffit? Gold Bond XP works great. Maybe your project requires Gold Bond eXP Interior Extreme for the ability to install the board prior to the building being dried in? In that case, use the same Gold Bond eXP Interior Extreme for the soffits. There’s no reason to have to specify an additional product.” Scott Hughes, Construction Design Manager, National Gypsum Company.

Your Product Selection Guide for Exterior Soffits and Ceilings

The primary factors you should consider for exterior ceiling and soffit installations are the finish, the fire rating and framing. You may apply some finishes to numerous substrates, such as Direct-applied Exterior Finish Systems (DEFS), while paint requires special surface treatment for some products.

The Finish

For painted surfaces, use paper-faced, mold- and moisture-resistance gypsum board, such as XP Fire-Shield Gypsum Board. You may also use glass-mat faced gypsum panels, such as Gold Bond® eXP® Sheathing or Gold Bond® eXP® Interior Extreme® Gypsum Board, but these products require an additional skim-coat of joint compound for a smooth, paintable surface. Use setting-type joint compounds, such as ProForm® Quick-Set Lite™ Setting Compound, for all exterior joint treatment and skim coat applications. Ready mix products are not approved for exterior use.

You may apply Direct-applied Exterior Finish Systems, or DEFS, to any of these soffit substrates: XP® gypsum boards, eXP® gypsum panels or PermaBASE® cement boards. So, utilize the products that are already being used on the project and available at the jobsite. We recommend you talk to your Construction Design Manager before specifying.

Fire-Rated Applications

For applications where the soffit is a component of a fire-rated floor- or roof-ceiling assembly, it is essential to verify that the soffit material is listed in the rated UL design. While some fire-rated assemblies allow for Type X products, most fire-rated floor- and roof-ceiling assemblies require enhanced, proprietary Type X gypsum boards known as Type C gypsum boards, such as Gold Bond® XP® Fire-Shield C™ gypsum boards and Gold Bond® eXP® Interior Extreme® Fire-Shield Type C™ gypsum panels.

Framing

Products have different framing requirements. Apply 1/2” gypsum board and 1/2” or 5/8” PermaBASE cement board to maximum 16” o.c. framing. Apply 5/8” gypsum board (XP gypsum boards or eXP gypsum panels) to framing up 24” o.c.

“There are many things to consider when selecting an appropriate exterior soffit substrate. Our Construction Design Managers are experienced industry professionals and have seen many different soffit installations. Connect with us and we can help you evaluate product selections based on your specific design requirements.” Alan Zeedyk, Construction Design Manager, National Gypsum Company.

@NationalGypsum #NationalGypsum #construct

For other relevant searches, you might want to try: