About Stretch Forming / Metal Curving

Stretch Forming / Metal Curving

People have been bending and curving metal for centuries, but stretch forming, born from the aerospace industry, maintains precise dimensions throughout a curve and produces perfectly contoured products while limiting, or even eliminating, wrinkling inside the arc.

Stretch forming is the process of forming sheets and profiles by the combined application of tensile and bending forces. Stretch forming keeps the extrusion under constant tension while wrapping it around a form, or die, to make parts into simple or complex contoured curves.

Benefits of Stretch Forming by Linetec

Linetec and Southern Stretch Forming will work together, striving to meet every need of our customer. However, there may be some cases that an extrusions configuration are not suitable for curving/stretch forming. Below are some broad overview capabilities, if your needs are outside of these capabilities contact us directly at [email protected] for assistance.

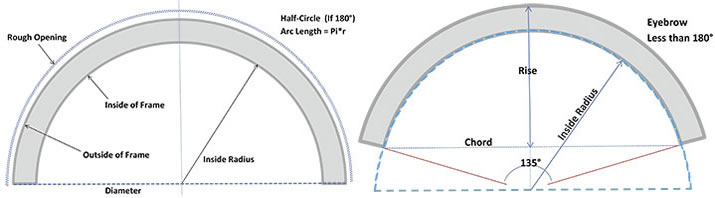

Half-Circle or Eyebrow Openings

Determine at what points the curve begins and ends. These points are called the tangent points (or straight-line points). Measure the distance between these points ideally with a laser measurer. This distance is called the chord. If the opening is a complete half-circle (180°), this distance will also be the diameter, and half of this measurement is your radius.

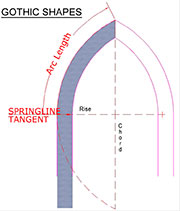

Gothic Shapes

Determine at what point along the side that the curve begins. This tangent point acts as the top of an arc that begins at the top of the pointed opening and extends through this tangent point and continues as an imaginary line until it intersects with the plumb line coming straight down from the upper point. This distance on the plumb line between these points is the chord.

The distance from the center of the chord (on the plumb line) measured horizontally to the beginning of the curve (or tangent point) is the rise.

If there are straight legs, measure from the tangent point (where the curve ends) straight down to the bottom of the piece.

Additional Notes

Stretch Forming

To deliver these stretch forming services, Linetec has teamed with Southern Stretch Forming, headquartered in Texas. The company will provide a full scope of bending capabilities on Linetec’s campus in Wausau, Wis., including annealing and tempering to soften and harden aluminum.

Stretch Form Capabilities

Stretch Form Guidelines

From the exact center of the chord, measure straight up to the top of the arc. Do not include any straight leg. This distance is called the rise (or height). If the rise is one half of the chord, then you have a complete half circle or 180°. See “Notes” below for a comment on inside vs. outside measurements.

If straight legs are required, measure from the tangent point (where the curve ends) down to the lowest point needed

Hang a plumb bob from the point of the Gothic opening.

Hang a plumb bob from the point of the Gothic opening.

Brochures | 3-Part CSI specifications | CAD details

Source: https://linetec.com

08 11 00 - Metal Doors and Frames

08 12 00 - Metal Frames

08 12 13 - Hollow Metal Frames

08 12 13.13 - Standard Hollow Metal Frames

08 12 13.53 - Custom Hollow Metal Frames