How to Minimize and Remove Concrete Efflorescence

Other News

Other News Subscribe to FREE newsletter

Subscribe to FREE newsletter

| Aug 14, 2024 |

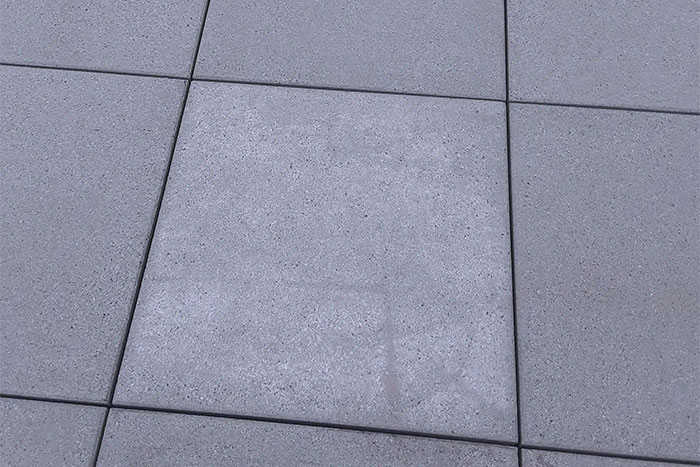

Concrete, pavers and other masonry are porous building material products that are prone to efflorescence — a chalky mineral deposit that appears on the surface. And although concrete efflorescence itself is usually not damaging to the concrete, it creates an unsightly blemish. Thankfully, it’s easily removed in most cases using the right cleaning techniques and tools.

But what causes efflorescence, should it be of concern and how can architects and contractors mitigate the chance of efflorescence forming during and after construction? Here you’ll find everything you need to know

A Brief Explanation Of Efflorescence And Where It Comes From

Efflorescence in concrete happens when moisture causes soluble salt within the material to rise to the surface. When the moisture evaporates, it leaves behind a white, powdery substance on the top layer of the concrete. It’s most often caused by water evaporation, low temperatures, humidity, condensation and rain and is thereby a naturally occurring process. Beyond built environments, efflorescence can happen in natural settings, too.

The unfortunate part of that reality is that completely preventing efflorescence on concrete is unlikely. However, contractors and architects can employ a few techniques that can help reduce the chance of efflorescence on their projects, and regular cleaning is often enough to keep it at bay if it’s particularly persistent

Does Efflorescence Compromise The Integrity Of Concrete, Pavers Or Other Masonry?

While efflorescence is an eyesore, it’s typically not a cause for concern from a build-quality or structural integrity perspective. That said, excessive efflorescence can be a sign of moisture intrusion, which may raise some flags about future structural damage or mold growth — however, that is rare.

How To Reduce The Likelihood Of Efflorescence On Concrete

While efflorescence is a naturally occurring process, there are a few techniques that can help reduce the severity or regularity of salts rising to the surface of the concrete.

Try one or multiple of these best practices before, during and after construction to help manage soluble salt rising to the surface:

Thoroughly Review Design Plans: This can help you determine if and where water may enter from and accumulate. Once you know this, you’ll be able to plan construction accordingly and include any necessary preventive measures, such as proper eaves, overhangs and flashing to reduce the chance of water absorbing into concrete.

Store Porous Building Material Off Of The Ground: Keeping concrete pavers and other materials prone to efflorescence up off the ground — and covered with waterproof sheeting, such as a heavy-duty PVC tarp — will limit the amount of water that gets absorbed before installation.

Use A Class F Fly Ash: Mixing a class F fly ash into your concrete mixture can help lessen the amount of calcium hydroxide in the concrete, thereby reducing the chance of efflorescence forming on the surface once it’s set.

Estimate Efflorescent Potential: While an industry standard doesn’t exist for resolutely determining efflorescent potential, architects can use ASTM C67-13: Standard Test Methods For Sampling And Testing Brick And Structural Clay Tile to estimate it. This can help contractors develop an idea of whether or not a particular concrete product will be a good fit for their project or not, taking into consideration the building environment, weather conditions and more.

Use Clean, Potable And Salt-Free Water: Water is a necessary ingredient for mixing and curing concrete. During construction, it’s important to use water that has low or no salt content as well as be mindful of water-to-cement ratios.

Use Quality Building Materials: High-quality concrete pavers are constructed with greater care and are put through more rigorous testing. This means they may be less porous and, therefore, less prone to efflorescence than cheaper options.

Seal The Concrete: Using a penetrating sealer will harden the concrete and make it less penetrable by water. While it may not totally prevent efflorescence from happening, it can reduce the likelihood. Keep in mind that, to effectively clean sealed concrete if efflorescence does occur, you will need to remove the sealer. This measure is more applicable to indoor concrete flooring.

These techniques can help reduce efflorescence in concrete, but builders and architects should keep in mind that 100% prevention is never guaranteed.

Effective Techniques For Efflorescence Removal

Luckily, when efflorescence does rise to the surface of concrete, it’s fairly easy to remove. Given its soluble property and the hardness of concrete, there are quite a few cleaning techniques that are effective in removing the surfaced salts.

Most methods involve abrading the surface of the concrete with a sturdy brush or lightly blasting it with water under pressure. Concrete should always be cleaned after installation. Subsequent cleanings to remove efflorescence can be carried out by property owners themselves or professionals depending on the size or severity of the case.

Here are a few effective methods for cleaning efflorescence:

Dry Brushing: The most straightforward way to clear concrete of efflorescence is to use a dry brush or rotary scrubbers and give the surface a good cleanse. If the salts are loose enough, this should do the trick to clean the area.

Light Water Blasting: Using water to clean efflorescence may sound counterintuitive, but water blasting is a quick and effective way to clean concrete pavers. Just make sure to dry the material completely afterward, as failure to do so will cause efflorescence to reappear.

Use A Commercial Efflorescence Cleaner: Commercial cleaners containing a weak acid solution can help neutralize and remove efflorescence as well as mitigate future occurrences.

Premier Architectural Products From Wausau Tile

Efflorescence can be a pain, especially when it shows up on your beautifully finished project. And while it may not be completely preventable, rest assured that high-quality building materials and the proper cleaning techniques will keep concrete looking its best for years to come.

For more than 70 years, Wausau Tile has demonstrated its dedication to quality, value and American craftsmanship. Our architectural pavers, site furnishings and custom precast concrete and terrazzo are unrivaled.

We're more than a manufacturer of exceptional architectural products — we're a creative, engaged manufacturing partner that helps you every step of the way. Contact us today for more information.

@WausauTile #WausauTile #architectural #pavers #sitefurnishing #terrazzo #precast #concrete #tile

For other relevant searches, you might want to try: